Whether you make frozen pizzas, baked goods, or ready-made meals, food manufacturers have many things to consider when it comes to ensuring the quality and freshness of their products and the smooth operation of their facilities. While product quality is paramount to the success of any food production plant, facility owners may stand to enhance operations even more by also focusing on the energy efficiency of their buildings and equipment, in particular, the energy-intensive refrigeration processes in use during production.

Spiral freezers, for instance, are a popular means of minimizing the overall refrigeration footprint thanks to their compact, streamlined design, but are significant users of energy and good candidates for improvement in efficiency. Through Veregy’s energy consulting work with food industry professionals utilizing spiral freezer technology, a variety of efficiency improvements have been identified which—when combined—have the potential to contribute significant, persistent energy savings year over year, while improving or maintaining the quality of food product being produced.

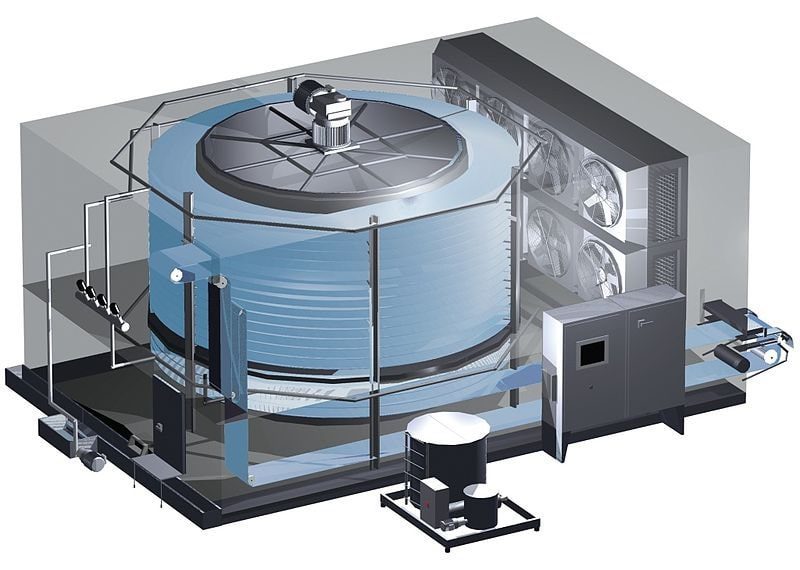

What is a Spiral Freezer?

In a typical frozen foods manufacturing facility, there are various types of industrial refrigerators employed to maintain consistent quality, texture, and temperature of products. Spiral freezers are one means of refrigeration that are popular with food processors given their compact, spiral belt and their ability to freeze large amounts of products with longer dwell times. Spiral blast freezing of food products is the most energy-intensive process in a typical frozen foods manufacturing facility with air temperatures regularly in the range of -10°F to -50°F depending on the type of product to be frozen.

Unlike tunnel freezers, which require a long, linear wire-mesh belt to convey products through a sub-zero blast-freezing room, spiral freezers use self-stacking, multi-tiered belts to maintain product quality and minimize the refrigeration space required in the plant. Most modern spiral freezers offer a level of customizability and are generally fairly easy to install on the plant floor.

How do Spiral Freezers Work?

Most spiral freezers employ mechanical or cryogenic refrigeration methods, and the use of high-velocity air pumped over the product in either a horizontal (crossflow) or vertical (downflow) arrangement. However, several airflow configurations are possible. More efficient airflow means faster freezing times, less product dehydration, and higher quality food delivered to the end customer. This also means less inventory waste and increased business opportunities as spiral freezers allow for higher freezing capacity without the need for additional human labor.

In cryogenic freezers, low-temperature gases such as carbon dioxide or liquid nitrogen are applied directly to the food resulting in faster freezing times and higher quality products. These systems generally have a lower capital outlay and offer improved flexibility and ease of cleaning. Mechanical freezers use circulating refrigerant to reduce temperatures through a heat exchange with the product. They are usually more expensive due to the required refrigeration systems but generally offer greater benefits over the long-term. In both cases, product is moved around a spiral conveyor in an insulated enclosure for a period of time before heading to the next process.

Improving the Energy Efficiency of Spiral Freezers

Spiral freezers are expensive to operate as they typically operate at low temperatures. Often the suction pressure of the plant’s refrigeration system (which defines the energy used in the refrigeration plant) is determined by the temperature needs of the spiral freezer. Most spiral freezer systems are not optimized as many of the key parameters such as airflow, entering and leaving temperatures are not controlled. Many of the manufacturing facilities employ multiple spiral freezers. However, by managing the entirety of the freezing process with the right advanced monitoring and controls systems in place, plant operators can achieve energy savings of between 30% to 50% or more on an annual basis. Potential energy saving solutions for spiral freezers include:

- Installing Variable Speed Drives (VSDs) for fans

- Increasing freeze time to allow for lower air velocities

- Improving operating procedures to minimize underuse

- Reduce discharge pressure setpoints

- Reduce maximum fan speed with lighter products

- Reduce the number of defrost cycles

- Add additional monitoring to the production line to monitor finished product temperature

Greater control over the spiral freezing process can yield additional benefits such as improved fault detection and automated record keeping—not to mention an overall improvement in product quality.

Example: Spiral Freezer Automation at a Pizza Plant

While factors such as air temperature, flow, and velocity are all important to consider when designing a spiral freezer, they do not tell the full energy story, especially because spiral freezers vary greatly in their freezing characteristics given the variety of applications and product types.

In recent tests with a customer who utilizes spiral freezers to make frozen pizzas, for instance, Veregy discovered a myriad of issues resulting in higher-than-desired energy intensity. It was found that, in many instances, the plant’s spiral freezers were being underutilized throughout the day with no product entering the freezer for more than 30 minutes at a time. Given that the frost buildup on the coils was unpredictable, the freezer’s defrost cycle was occurring too frequently, compounding the existing underuse of the equipment, resulting in even more wasted energy and additional unwanted downtime. Excessive air infiltration at both the infeed and outfeed conveyors of the spiral freezer further increased the defrost demand.

Our engineers concluded that by building an advanced automation platform to integrate the refrigeration system and loads in the manufacturing process, the automation system would provide and contribute to persistent energy savings year over year. Further savings were derived by reducing the number and duration of the defrost cycles based on the differential temperature across the evaporator coils.

Additional monitoring was added to the production line to record the core temperature of the finished product in the Packaging Area. The data is now automatically recorded into the database, which is shared with the Quality Assurance Department, replacing the process of manually recording the data on paper and re-entering the data on a computer. This reduced labor costs and improved the accuracy of the finished product records.

As discussed previously, spiral freezers are significant users of energy. The utilization of advanced monitoring and controls can result in improved product quality and energy savings. Deploying spiral freezer controls in your plants can lead to a significant benefit to the bottom line.