Imagine you’ve made a significant investment—your motivation for purchasing being a single crucial feature. Perhaps it’s a new laptop with a longer battery life or an electric vehicle with an extended range. In the event the laptop runs out of battery prematurely, or the vehicle’s range is only half the advertised distance, you’re likely not only to be frustrated but eager to get back every penny you paid for services undelivered.

Now imagine your motivation for energy efficiency projects. In this case, the need to accurately assess whether an Energy Efficiency Measure (EEM) is achieving the desired energy and cost savings is paramount. This need to validate and verify savings has come to the forefront as more and more businesses, manufacturers, and institutions look to improve their bottom line and overall sustainability via energy efficiency projects.

Measurement and Verification (M&V) is the process of analyzing the effectiveness of implemented EEMs to validate efficiency improvements meet or exceed expectations. M&V is a crucial strategy that not only can demonstrate whether EEMs are performing or underperforming but can also help to identify additional opportunities for energy savings and improved operational efficiency.

What is Measurement and Verification?

Measurement and Verification (M&V) refers to the overall strategy and systematic process of quantifying the energy savings of implemented projects. The purpose of M&V is to determine the pre-implementation and post-implementation energy usages to determine the savings resulting from the implementation of any energy projects. By comparing energy use before and after, difficult-to-assess project economics and impacts can be quantified, and opportunities for further optimization can reveal themselves.

There are many factors that can impact energy savings performance, including variations in building loads, weather fluctuations, and production variability. M&V normalizes-out variability of these independent factors to provide a true measure of EEM energy savings with all other factors being equal. Without a weather-normalized M&V approach, chiller-related savings could be overstated in the summer or understated in the winter. If production increases 25% over the course of an energy project and the site energy usage increases, M&V can quantify if the energy project is underperforming or if the savings are being achieved on a production-normalized basis. Overall, the intent of M&V is to use data, statistics, and calculations to remove subjective judgment of energy performance in complex systems with many independent variables.

M&V is frequently used in energy efficiency projects and other conservation efforts where energy savings must be verified and where enhanced system transparency and visibility are crucial. In some cases, the process may also be mandatory in confirming that savings’ guarantees are met. M&V provides operational insight related to energy projects, which allows teams to allocate risks appropriately and better understand system interdependences when implementing energy projects. This provides confidence and transparency on the impact of EEMs when planning future energy projects.

How is Measurement and Verification Done?

M&V methods vary depending on the efficiency measure in question. Still, most projects adhere to a set of best practices defined by the Efficiency Valuation Organization and the International Performance Measurement and Verification Protocol (IPMVP). The IPMVP provides techniques for verifying the impact of energy efficiency, water efficiency, and even renewable energy projects. The IPMVP framework requires certain M&V activities to take place in each project to ensure consistency across projects and accurate energy savings calculations for either a whole facility approach or individual energy efficiency measures.

The IPMVP framework complements several other national and regional energy efficiency guidelines, including the U.S. Department of Energy’s Federal Energy Management Program (FEMP) and ASHRAE Guideline 14: Measurement of Energy, Demand, and Water Savings. These guidelines provide a consistent set of standards and define key statistics to ensure high quality, transparent, and defensible M&V.

The M&V process is a defined start-to-end process starting with data gatherings via building-level and sub-building-level meters, data analysis, data normalization for key energy drivers (weather, occupancy, production), reporting, and third-party verification. Computational methods and statistics are applied to regression-calculated normalized baselines to define energy savings and quantify confidence levels and savings uncertainty.

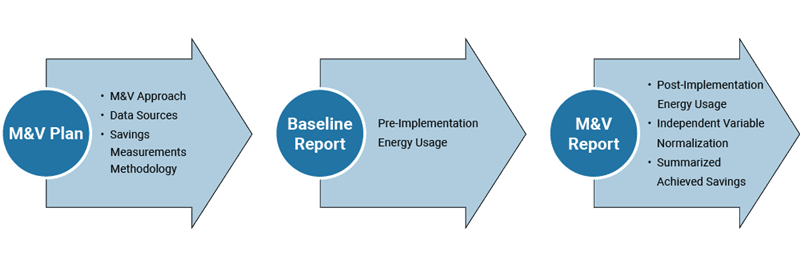

Though each project has a unique application of IPMVP, some applications will have similar methods in their M&V implementation and deliverables. Each M&V project will include an M&V Plan, which defines the M&V approach, system boundaries, data sources, and details for how savings will be measured; Baseline Report, which defines the energy usage of the site prior to implementation; and M&V Report, which presents the post-implementation energy usage, details independent variable normalization, and summarized achieved savings.

Why Measure and Verify?

Verifying accurate energy savings is a necessary part of the design of any energy program, as is how any energy efficiency measures will impact existing systems or operations. Through Measurement and Verification (M&V), a systematic approach is employed to validate the true impact energy efficiency investments have on a business’s bottom line. M&V is typically a snapshot in time encompassing a project or EEM, but it can be used to track a building’s energy performance over time to evaluate the persistence of savings and identify potential continuous commissioning issues before they snowball.

Whether you are considering a chiller replacement, lighting upgrade, or a whole-building retro-commissioning project, all manner of projects can benefit from M&V to ensure realization of energy and cost savings. Veregy’s team of M&V specialists are skilled in designing and implementing custom M&V approaches to ensure your energy projects meet expectations year after year. Contact us today to discuss your efficiency project.