It’s always important to make sure that an investment delivers the promised performance. The larger the investment, the more critical performance tracking is, especially for energy efficiency projects. A building’s energy efficiency performance is tracked through a process called Measurement and Verification (M&V). Through planning, data collection and analysis, the M&V process creates a verifiable report of a building’s energy savings. The International Performance Measurement and Verification Protocol (IPMVP) was created to standardize the M&V process for energy, water, and renewable energy projects. Since its inception in 1997, the IPMVP has grown to become the preeminent M&V protocol used by new development and retrofit projects worldwide.

What is the International Performance Measurement and Verification Protocol?

The IPMVP was created by the Efficiency Valuation Organization (EVO), a global non-profit that creates products supporting and encouraging energy efficiency projects. The IPMVP provides techniques for verifying the impact of energy efficiency, water efficiency, and even renewable energy projects. The protocol complements several other national and regional energy efficiency guidelines, including the U.S. Department of Energy’s Federal Energy Management Program (FEMP) and ASHRAE Guideline 14: Measurement of Energy, Demand, and Water Savings. The IPMVP requires certain M&V activities to take place in each project to ensure consistency across projects and accurate energy savings calculations for either a whole facility approach or individual energy efficiency measures.

The IPMVP contains a range of proven M&V methodologies and principles so that each project can be customized based on appropriate cost, accuracy, and technology requirements. The latest iteration, IPMVP Core Concepts, lays out all of the attributes needed for a fully adherent M&V process. The IPMVP Core Concepts and additional supporting guides and resources are available for free at the EVO website.

Who Uses the International Performance Measurement and Verification Protocol?

The IPMVP uses common principles that are widely accepted for any M&V process. Some of the most common user groups are:

- Energy performance contractors on behalf of a building customer, especially Energy service companies (ESCOs),

- Energy consultants quantifying the energy savings realized from retro-commissioning (RCx) or other energy savings projects,

- Energy users tracking savings of their own retrofit,

- Facility managers accounting energy budget variance or looking for recognition of environmental efficiency,

- New building designers, especially when seeking a sustainability certification such as LEED,

- Utility demand-side management designers, and

- Water efficiency or emission reduction project developers.

How Does the International Performance Measurement and Verification Protocol Work?

The M&V methodologies included in IPMVP boil down to the equation:

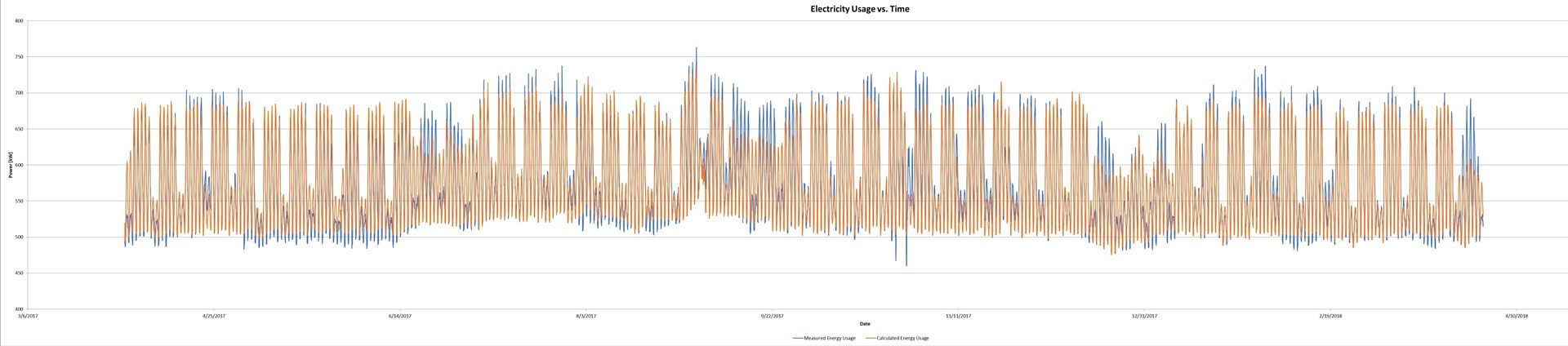

Savings = (Baseline Period Energy – Reporting Period Energy) +/- Adjustments

To measure savings, baseline data must be established before any energy efficiency measures (EEMs) are implemented. The baseline period tracks not only energy consumption but also other operational data such as occupancy levels, HVAC schedules, production throughput, etc. After EEMs are implemented, the reporting period begins. Meters throughout the facility gather data that is supported by quality assurance programs and third-party verifications. The difference in energy consumption from baseline to reporting period shows the savings, with adjustments as one crucial caveat.

Adjustments are used to balance out the planned and unexpected variations that occur during the reporting period. These can be routine, like weather and production volume, and non-routine, such as shifts in the production schedule or facility renovations. All of these variations affect the energy consumption bottom line, so they must be accounted for to get accurate savings data. Routine adjustments are typically accounted for by normalizing the energy use data against weather, production, occupancy, or other data that is readily available. Non-routine adjustments are more complex but still need to be accounted for on a case-by-case basis.

The Four International Performance Measurement and Verification Protocol Approaches

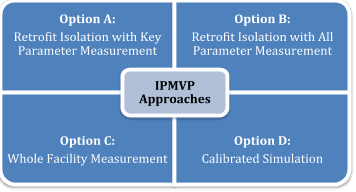

There are four general approaches within the IPMVP standard that can be tailored to the specific energy saving project needs and constraints:

Each of the four options requires energy, building, and/or operational data for determining energy savings. Option selection involves consideration of numerous aspects including location of the EEM measurement boundary and the availability and/or reliability of the measured or estimated data.

Option A: Retrofit Isolation with Key Parameter Measurement

The first M&V option is the Retrofit Isolation with Key Parameter Measurement approach meant for energy efficiency projects isolated from the rest of the building. It is most appropriate for relatively simple EEMs whose baseline and post-installation conditions are dependent on a few key parameters, such as lighting input power or chiller efficiency. Typical applications may include a lighting retrofit, where the power drawn can be monitored and hours of operation can be estimated, or a chiller retrofit, where power consumption or flow rate can be trended before and after implementation, but with no consideration of the interactions the individual system has with other building systems.

This first method is generally the lowest cost M&V approach as baseline and post-implementation usage can be estimated using limited data collection plus engineering analysis of measurements of critical system parameters. Savings are determined by field measurement of the key performance parameter(s) which define the energy use of the EEM affected system(s) and/or the success of the project. Measurements are short-term, periodic, or continuous, and are taken at the component or system level for both the baseline and the retrofit equipment. Parameters not selected for field measurement are estimated. Estimates can be based on historical data, manufacturer’s specifications, or engineering judgment. Documentation of the source or justification of the estimated parameter is required.

When using the Retrofit Isolation with Key Parameter Measurement approach, it is critical to verify proper ongoing operation of the implemented measures. The accuracy level is dependent on the validity of estimates, the quality of the equipment inventory, the measurements made, the frequency of those measurements, and the sample size (if a sampled approach is taken). When correctly applied, Option A ensures that baseline conditions have been properly defined, confirms that the proper equipment/systems were installed and that they have the potential to generate predicted savings, and verifies that the installed equipment/systems continue to yield the predicted savings over the life of the equipment.

Option B: Retrofit Isolation with All Parameter Measurement

The second approach to M&V is the Retrofit Isolation with All Parameter Measurement. It is similar to the first approach except instead of looking at individual EEMs, such as a chiller replacement or a lighting retrofit, all relevant performance and operational parameters are measured to provide long-term data on the energy use and savings of the measures. Typical applications may include a lighting retrofit where both power drawn and hours of operation are recorded. This approach is especially useful where submeters already exist that record the energy use of subsystems under consideration, such as a separate submeter for heating, ventilation and air conditioning (HVAC) systems.

This retrofit isolation or system level approach can be more expensive and difficult than Option A but it typically provides a higher level of accuracy when calculating energy savings since the measurements used in Option B are more precise than the estimations used in Option A. In this case, savings are determined by field measurement of all key performance parameters which define the energy use of the EEM affected system. More importantly, continuous monitoring of any retrofit investments can enable further optimization of systems and equipment over time. When variations are expected, it is appropriate to measure factors continuously. Short-term or periodic measurements are also common for constant load measures with little variability.

Aside from the subsystem situation described above, the Retrofit Isolation with All Parameter Measurement approach is also a viable approach if energy savings values per individual measures are desired. Option B can also be a good choice when interactive effects can be allocated appropriately and when operational data on the equipment are readily available through control systems.

Option C: Whole Facility Measurement

The third M&V option is Whole Facility Measurement, which is a whole-building verification approach that looks at facility-level metered data rather than the performance of individual conservation measures. Put another way, this method looks at the overall energy use in a facility and the effectiveness of all measures collectively, including how they interact with one another. If a project includes several EEMs, it can prove difficult to measure the effectiveness of the individual measures if there is an interaction between systems, for example, lighting retrofits impacting HVAC heating and cooling loads.

This whole-building verification method determines savings by measuring energy use at the whole facility or sub-facility level. It looks at energy savings based on actual consumption data from utility data. It typically uses techniques such as multivariate regression analysis or similar methods to account for facility-level changes in operations, occupancy, or other independent variables such as weather and production variability. Raw data used for Option C analyses should be in 12-month datasets to avoid amplifying seasonal variations. It is also necessary to specify how site changes unrelated to installation of EEMs will be tracked over the performance period and how the data will be used to perform savings adjustments.

When using Option C is it important to specify all independent variables that affect energy consumption, whether or not they are accounted for in the model, the form and content of any separate performance models (if used) as well as demonstration of the statistical validity of the final regression models. As independent variable data must correspond to the time periods of the utility data dates and intervals, a plan for data collection, including sources and frequencies, should be specified.

Option D: Calibrated Simulation Measurement

The fourth M&V approach is the Calibrated Simulation Measurement. It is also a whole building method, but unlike Option C, the whole building approach in Option D can be used for individual components. This method is particularly useful in the case where there is limited baseline utility data or several interrelated EEMs. When determining savings through simulation of the energy use of the whole facility, or of a sub-facility, the latest U.S. Department of Energy M&V Guidelines for Performance-Based Contracts (Version 4.0) recommends using an experienced building modeling professional, who can fully understand simulation software program capabilities and real data requirements for more accurate results.

Option D uses computer software to create calibrated simulation models that are capable of determining energy savings either at the component or building level. Depending on the available inputs such as persistent energy usage data or historical weather data, these models can be calibrated to significantly improve the accuracy of the energy savings estimates. Measurement data from individual components and systems may also be included, further refining these models. This may include spot measurements and short-term monitoring of key parameters for both the baseline and performance period models capturing the full range of the equipment’s operation.

The Calibrated Simulation Measurement approach usually requires considerable skill in calibrated simulation. Aside from following the recommendation to use an experienced building modeling professional, the Option D project-specific M&V plan should also determine the availability of utility data, whether hourly or monthly data are available, and whether sub-meters can be installed to collect interval data of key subsystems. It is also important to specify model calibration procedures used for monthly, hourly or subsystem data for both the baseline and performance period models and to specify the simulation program and the source of weather data used.

Because of the need to clearly explain how savings will be calculated after the first year and the expense of keeping the models up to date, projects without expected substantial site changes may find the Option C Whole Facility Measurement approach more viable and cost effective than the Option D Calibrated Simulation Measurement approach. However, regardless of how savings are calculated each year, the ongoing performance of the measures should be periodically verified.

IPMVP Approaches Comparison Chart

| Applicable Options | ||||

| A | B | C | D | |

| Savings or operations within the measurement boundary are variable | x | x | ||

| EEMs need individual assessment | x | x | x | |

| Facility uses many types of EEMs | x | x | ||

| Interactive effects can be reasonably estimated or ignored | x | |||

| Low risk of not achieving savings | x | |||

| Expected savings are less than 10% of the utility meter | x | x | x | |

| Low magnitude of savings for the full project or a portion of the applicable project | x | x | ||

| Equipment submetering is available | x | x | ||

| Uncertainty created by estimations is acceptable | x | |||

| Multiple future changes are expected within the measurement boundary | x | x | ||

| Long term performance assessment is needed | x | x | x | |

| Significance of some energy driving variables is not clear | x | x | x | |

| Meters added for isolation purposes will be used for other reasons (like operational feedback or tenant billing) | x | |||

| Whole facility energy performance assessment is needed | x | x | ||

| EEM interactive effects are complex and significant, or unmeasurable | x | x | ||

| Utility data available and regression analysis performance is acceptable | x | |||

| Measurable savings compared to the variance in baseline and reporting periods | x | |||

| Reasonable correlations possible between energy consumption and demand and other independent variables | x | |||

| Baseline period energy data is unavailable or unreliable | x | |||

| Computer simulation skill is available | x | |||

Why Is IPMVP Important?

If energy efficiency measures (EEMs) are going to be employed in a building or industrial process, tracking of energy and cost savings is key for reporting and ensuring successful outcomes. The larger and more complex the project, the more important it becomes for M&V efforts to adhere to the IPMVP guidelines. The IPMVP approach allows the M&V effort to easily scale with the size and scope of the EEMs implemented.

IPMVP is crucial if contracting with an energy service company (ESCO) that has its compensation linked to the actual energy cost savings. An IPMVP adherent measurement and verification (M&V) savings report should present savings in a transparent manner that can be readily reviewed and accepted by the customer, utility, and third-party reviewer. Beyond ESCO contracts, the added credibility and documented standards of IPMVP is essential when promoting the achieved energy savings by a facility or process. Robust M&V protocols gain public acceptance of energy efficiency projects while encouraging investors and other stakeholders to pursue additional projects in the future.

Whether you are considering a chiller replacement, lighting upgrade, or a whole-building retro-commissioning project, all manner of projects can benefit from M&V to ensure realization of energy and cost savings. Veregy’s team of M&V specialists are skilled in designing and implementing custom M&V approaches to ensure your energy projects meet expectations year after year. Contact us today to discuss your efficiency project.